Mandatory audits of buildings are required in each state for annual fire safety statements plus reviews to Dangerous Goods Facilities and disclosure of risk for insurance renewals.

This now includes EPS and ACP external Wall cladding and Non-Conforming Products for construction industry. The audits we offer are a rigorous examination for goods storage, handling with fuels, chemicals, site packaging and warehousing and we establish your business exposure from fires and environmental damage. We follow industry based audit schemes and can offer AS/ISO 31000 reporting.

We can assist with any dangerous goods storage design, AS1940 manifest arrangements, building code provisions, evacuation processes, fire engineering for hazardous goods, classes from class 1 explosives through to class 9 miscellaneous. Audit reports are needed for your Insurance representatives protection and satisfy “policy disclosure” aspects, to keep you trading and offer fire authorities updated risk controls.

Our team assesses all aspects of your project and can prepare comprehensive briefs and risk studies, to identify key issues in managing the processes associated with the manufacture, storage, transport, transfer, high piled storage and use of products and dangerous goods by undertaking rigorous code compliance audits and hazard analysis.

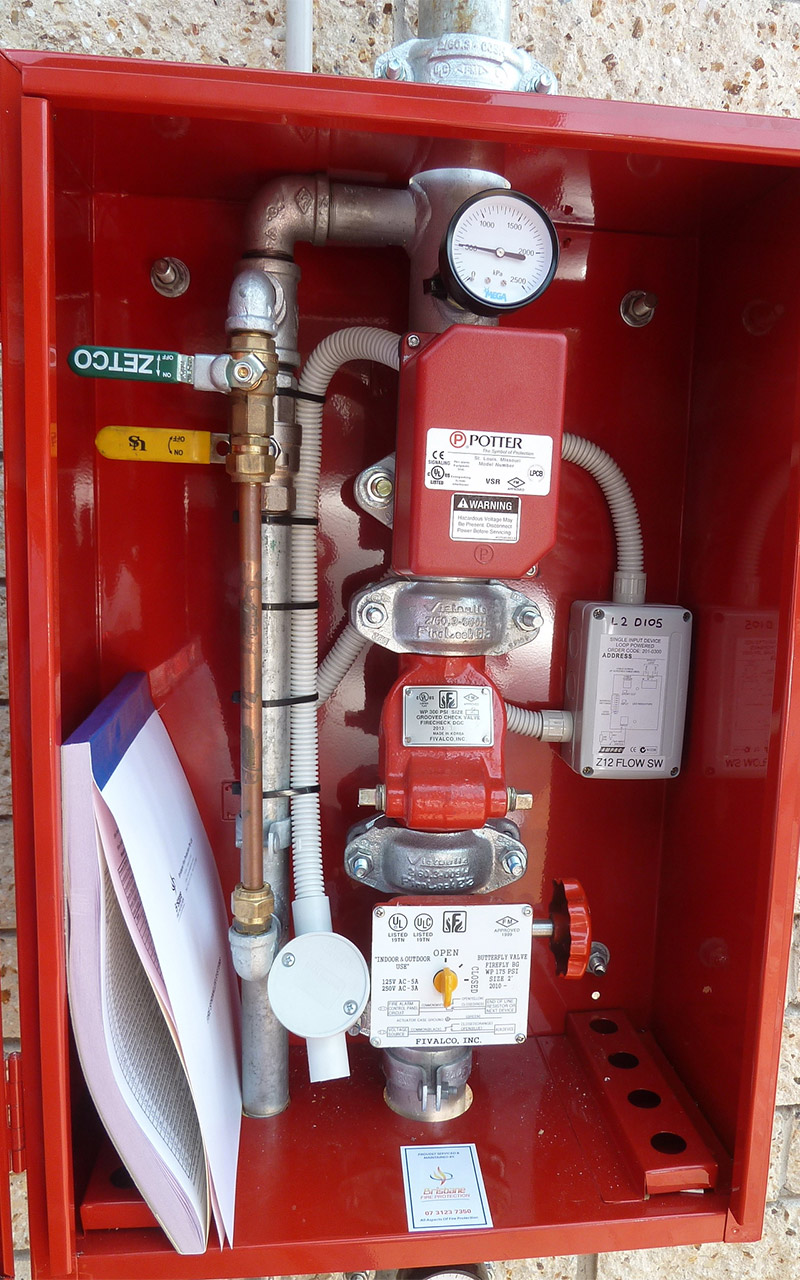

Any exposure discovered needs to be identified and reported to satisfy state authorities, councils, insurance representatives on a regular basis. We can tailor a program of review and support your maintenance team and partner with your business the regulatory AS1851, AS1940 and WHS codes.

Some states have changed their rules regarding fire fighting foam containing PFOS, PFOA. Clients will need to develop property solutions for containment and controls to meet these new EPA regulations. The approach to each has to be adapted to local regulations, the hazards and goods at risk and that means the risk from fire will be different as well. We conduct assessment of foam systems currently using AFFF for disposal and Fluorine Free Fire Fighting Foams (FFF) replacements solutions on established plant and processes. There is no one FFF replacement foam that works on all systems, so careful design is required or fire systems simply will not perform and EPA fines will result.

Our ACP & Cladding risk audit team are well into the final stages of the 3 Stage (SFS) review, testing process for clients and their regulatory reporting and we are now offering Stage 4 to document your ACP cladding solutions for the building and construction phase approvals to implement risk mitigation fire safety options and replacement on ACP and EPS combustible Cladding walls.

For Building ACP or ACM cladding and combustible external walls, fire protection systems, dangerous goods, High Piled Storage, detection services, emergency lighting and egress and transport provisions, data rooms, foam suppression, mechanical and energy systems, passive fire and NCC compliances – FERM Engineering can support and partner with you to create innovative fire performance solutions and find a pathway to maintain code compliance.